Customized candle glass bottle wholesale: high white material technology and multi-scenario solutions

Core advantages at a glance

- High light transmittance material: Using high white glass raw materials, the transmittance is more than 92%, fully showing the color and texture of the candle.

- Heat-resistant and leak-proof design: The bottle mouth adopts a double-layer sealing ring process, which can withstand a temperature difference of -20℃ to 150℃, and is suitable for hot-melt materials such as soybean wax and jelly wax.

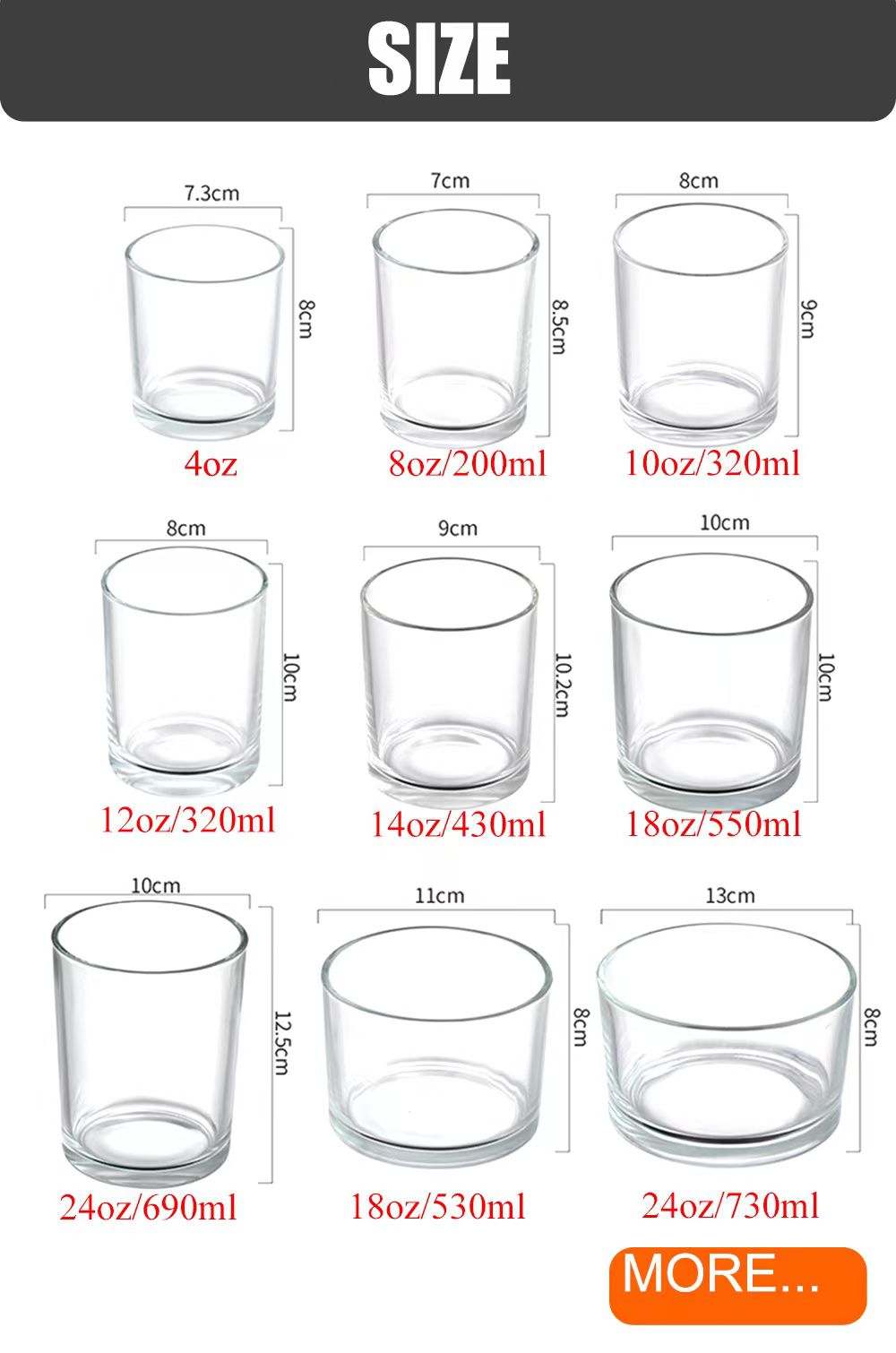

- Flexible production system: Supports 12 standard capacities from 200ml to 1000ml, compatible with mixed batch packaging, and a single container can combine 6-8 different bottle types.

Application scenario analysis

Home aromatherapy

The 250ml tea-colored bottle is matched with a bamboo bottle cap, which effectively blocks ultraviolet rays and prolongs the shelf life of the active ingredients of essential oils.

Festival decorations

The embossed pattern and gradient color process are suitable for Christmas, wedding and other themed candles to enhance the visual layering.

Functional container

The 380ml wide-mouth bottle is suitable for mosquito repellent wax and air purification wax, and the bottle wall thickness of 3.2mm ensures high temperature stability.

Supporting component options

| Component type | Material options | Functional characteristics |

|---|---|---|

| Sealing cover | Metal/ABS plastic/cork | Anti-oxidation design, suitable for cross-border logistics and transportation1 |

| Outer packaging | Corrugated box/EPE pearl cotton | Compressive strength ≥600kg/m³, support LOGO printing |

| Auxiliary accessories | Candle wick holder/measuring cup set | Improve the efficiency of wax filling process by 30%6 |

Customized service module

Surface treatment process

- Frosting gradient: achieve the contrast effect between frosted and bright areas

- Three-dimensional baking: support 3D embossed text and patterns, depth 0.5-1.2mm

- Electroplating coloring: 6 metallic gloss options including rose gold and champagne are available

Deep processing capability

The company’s own mold workshop can complete the development of new bottle types within 15 days, and supports customization of special-shaped bottles with a diameter of 6-15cm.

Supply chain guarantee system

- Quality control standards: 15 quality inspection processes, with a breakage rate controlled within 0.3%

- Logistics solution: 48 hours to warehouse in East China/South China, supporting trade terms such as FOB and CIF

- Order response: 10,000 standard products are delivered in 3 days, and 50,000 custom orders are completed in 15 working days

Global hot-selling market

Mainly exported to North America (accounting for 38%), Western Europe (27%), Japan and South Korea (15%), and adapted to UL, CE and other certification requirements

MOQ

- Standard products: 20,000 pieces/item (supports mixed batch of 6 items)

- Customized items: 50,000 pieces/item (including exclusive mold development)