Product Advantages

The 500ml amber swing-cap glass bottle is designed for beverage storage needs, taking into account both practicality and visual communication effects with industrial standards:

- Long-lasting sealing structure: The metal buckle and food-grade rubber gasket form a physical barrier that can maintain airtightness for more than 6 months to ensure the secondary fermentation effect of carbonated beverages.

- Photosensitive material protection system: The amber glass material filters 99% of ultraviolet rays, effectively delaying the decomposition of hops and the attenuation of yeast activity.

- Multi-scenario adaptation design: The bottle body is 3.2mm thick and has passed the 0.4 joule impact test, which is suitable for high-speed operation of filling lines and cold chain transportation environments.

Functional application areas

This product meets the packaging needs of mainstream beverage companies around the world:

- Fermented beverages: craft beer, kombucha, cider and other products that require secondary fermentation

- Functional liquid storage: cold brew coffee, herbal infused oil, handmade syrup

- Commercial display scenarios: bar customized cocktail bottles, restaurant chain exclusive sauce bottles

Personalized customization solutions

Provide a full-process brand packaging solution:

| Customization type | Process parameters | Applicable scenarios |

|---|---|---|

| Screen printing | Four-color overprinting accuracy ±0.15mm | Brand LOGO permanent logo |

| Hot stamping process | Gold foil thickness 0.12-0.15μm | Limited edition product packaging |

| Frosted treatment | 270 mesh diamond sand uniform atomization | Anti-slip grip area optimization |

| Relief engraving | CNC accuracy 0.01mm | Exclusive number for commemorative edition |

Industrial-grade deep processing capability

The production system has passed ISO 22000 food safety certification, with special configuration:

- Bottle mouth strengthening treatment: Flame polishing technology eliminates micro cracks, and the bursting pressure value reaches 1.8Mpa

- Stress relief system: Stepped annealing kiln makes the glass stress value ≤4 levels

- Clean packaging line: 100,000-level purification workshop completes automatic labeling and vacuum packaging

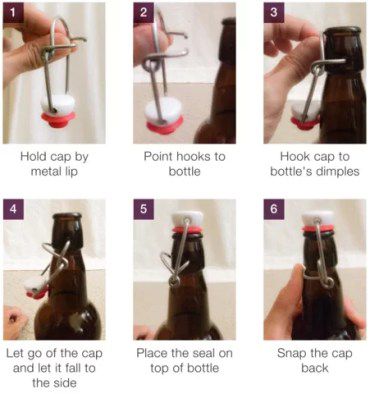

How to Assemble Swing Top Bottles

Assembling the swing top mechanism is simple and efficient. Follow these steps:

- Hold the cap by the metal lip.

- Point the hooks towards the bottle.

- Hook the cap onto the bottle’s dimples.

- Let go of the cap, allowing it to fall to the side.

- Place the rubber seal on top of the bottle opening.

- Snap the cap back into place, ensuring a tight seal.

Once assembled, the swing top bottles are ready for immediate use. This design is user-friendly, making the bottling process faster and more efficient for home brewers and manufacturers alike.

Global supply chain service

20 years of professional glass container manufacturer, service network coverage:

- European market: Establish technical adaptation with filling equipment manufacturers such as KHS and Krones

- North American channel: Passed FDA certification and supports direct delivery from Amazon FBA warehouses

- Asia-Pacific hub: Qingdao/Ningbo Port has 3 express ships per week, reaching Los Angeles Port on the 15th

Step-by-step procurement policy

Implement a transparent bulk pricing mechanism:

- Basic order: Full cabinet mixed loading (40HQ can accommodate 31,920 pieces)

- Strategic cooperation: Customers with annual framework agreement enjoy exclusive warehousing management

- Emergency order: 72-hour production for urgent orders below 15,000 pieces

Target market distribution

Mainly serving the following high-growth areas:

- Craft beer workshop (benchmarking Stone Brewing and BrewDog operating models)

- Organic food chain brands (refer to Whole Foods product line expansion needs)

- Hotel and catering groups (to meet the customized procurement of companies such as Marriott)

Quality verification system

Each batch of products passes:

- Internal pressure test: 1.6Mpa for 3 minutes without leakage

- Vertical load detection: ≥150kg axial pressure

- Hot and cold shock test: 0-80℃ temperature difference cycle 20 times

(Note: Specific technical parameters and certification documents can be obtained from the product white paper)

Technical consultation channel

The engineering team provides:

- Filling line adaptation solution (applicable to Krones Innofill series)

- Packaging optimization suggestions (reduce transportation damage rate to less than 0.3%)

- Regulatory consultation (comply with EU 1935/2004 food contact material standards)

Remarks: Product specifications may be fine-tuned due to technology upgrades. Please contact the technical consultant to obtain the latest parameter table. The production raw materials are high-white glass, and high borosilicate materials are not used. For detailed physical and chemical indicators, please refer to the COA report.