I have worked in the glass packaging industry long enough to see trends rise and fall, furnaces rebuilt, and molds worn smooth after millions of formations. Over the past decade, my role as a factory engineer has been less about sitting behind a desk and more about standing beside furnaces, adjusting forehearth temperatures at inconvenient hours, troubleshooting forming issues, and walking production lines with overseas customers who want to understand how their bottles actually come to life.

Many buyers—especially first-time importers—assume glass bottle production is a simple, automated affair. But the process is a long chain of chemistry, heat management, mechanical precision, and coordination between man and machine. And when one link slips, the final product tells the story immediately.

In this article, I’ll explain how a glass bottle is made in real factories (not in theory), using practical experience and several real cases I have handled for companies such as West Coast Bottles, Saxco, InnovativeSourcing, and Country Malt Group. This is not a textbook explanation; it’s the view from the factory floor.

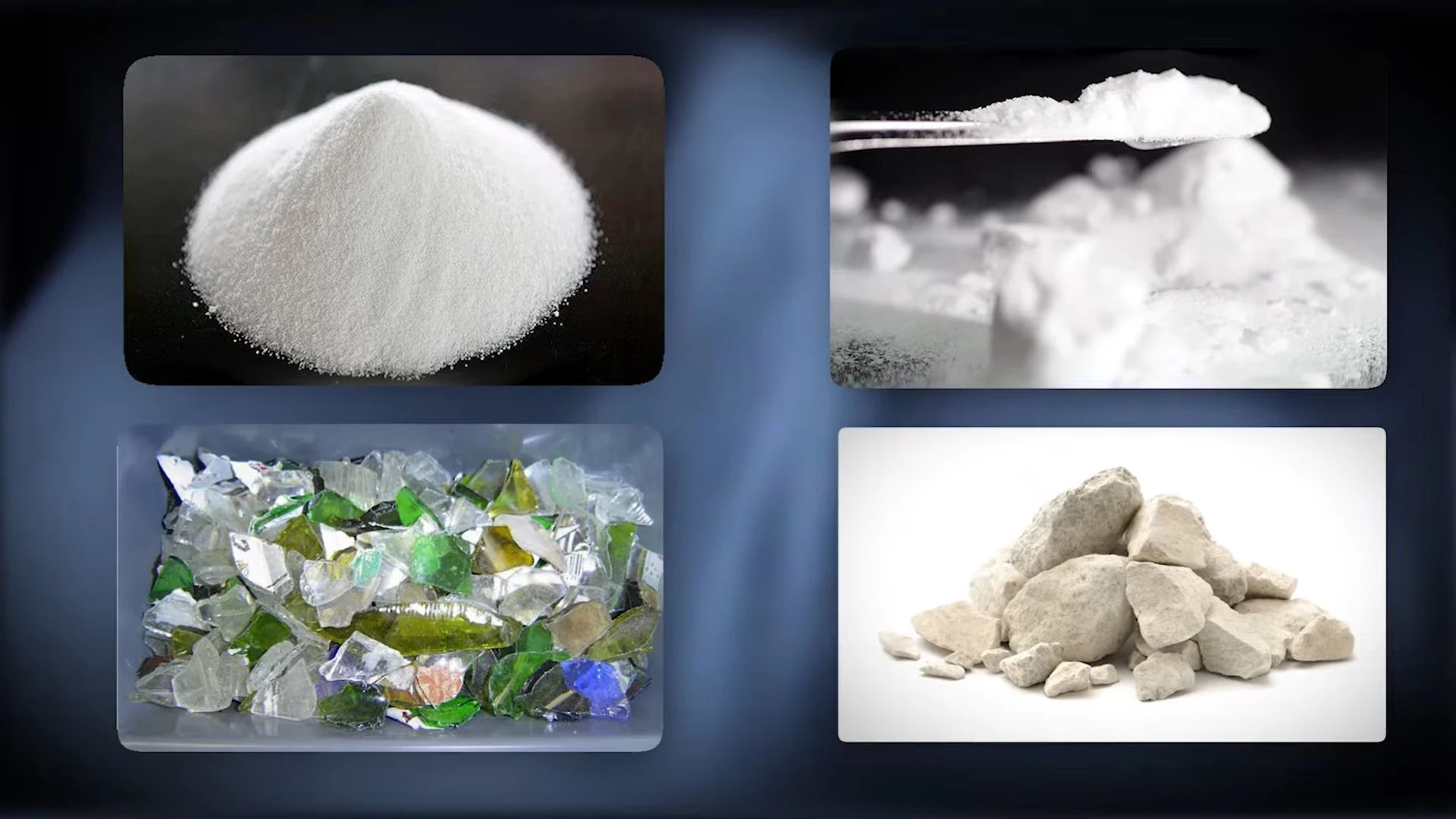

1. Glass Bottle Raw Materials

Almost every defect you see in a finished bottle—discoloration, cords, tiny stones, bubbles—can be traced back to the raw material stage.

Our standard composition includes:

- Silica sand as the structural backbone

- Soda ash to reduce melting temperature

- Limestone for durability

- Cullet (recycled glass) for melt efficiency

High-end flint bottles require low-iron sand and a lower cullet percentage. If cullet quality is inconsistent, the entire melt becomes unpredictable.

Case: Extra Flint Bottle for West Coast Bottles

We once prepared a run of extra flint bottles for West Coast Bottles. Their brand needed extremely clear glass—practically colorless. Extra flint material is unforgiving. During that project, we found the iron content slightly above target, which gave the melt a faint greenish tint. You would barely notice it unless you put two batches side by side, but that’s exactly the type of difference that matters to premium brands.

We had to adjust the batch formula on the same day—reducing cullet, checking sand moisture, and recalibrating the raw mix before it entered the furnace.

Raw materials look simple, but the bottle’s “personality” starts here.

2. Glass Melting Process

A furnace is the heart of the factory, and to people who visit for the first time, it looks like a giant, glowing cave. The mixture melts at roughly 1,500°C, and at that temperature almost everything becomes fluid—except the engineer’s sense of caution.

A small temperature drift can produce defects for hours before anyone notices.

Over-melted glass loses viscosity; under-melted glass forms cords. Both are problems.

Most people don’t realize that furnace stability is not constant. Fuel variation, air intake, refractory aging, and even seasonal humidity affect melt behavior.

Case: Surface Cords Noted by InnovativeSourcing

InnovativeSourcing once reported faint surface “strings” on a batch of clear bottles. These cords were barely visible unless you held the bottle under angled white light.

We pulled the melt report from that week and immediately noticed a pattern: the glass temperature in the right-side combustion zone fluctuated roughly ±18°C during peak hours.

The culprit? A clogged natural gas nozzle.

That single issue produced cords for nearly six hours before stabilizing. This is why furnace operators walk the platform constantly, listening and watching for subtle changes.

3. Forehearth Temperature Control

Before reaching the forming section, molten glass travels through the forehearth—a long temperature-controlled channel that adjusts the viscosity to the exact range needed for bottle forming.

The forehearth is much more sensitive than most people think. A 5°C difference can create:

- parison weight variation

- uneven wall thickness

- off-centered bottles

- lean and sagged shoulders

Case: Ovality Issues for Country Malt Group

Country Malt Group ordered a large run of amber beer bottles. During routine sampling, we found that a portion of the bottles were slightly oval—still within tolerance, but too close for comfort given their filling line speed.

When we checked the forehearth data, zone 3 had a gradual 12°C drop over several hours.

It wasn’t enough to create visible deformation, but enough to disturb gob viscosity.

We recalibrated the zone, cleaned the burner blocks, and the ovality returned to normal.

Good forming starts with good gobs. Everything downstream depends on this.

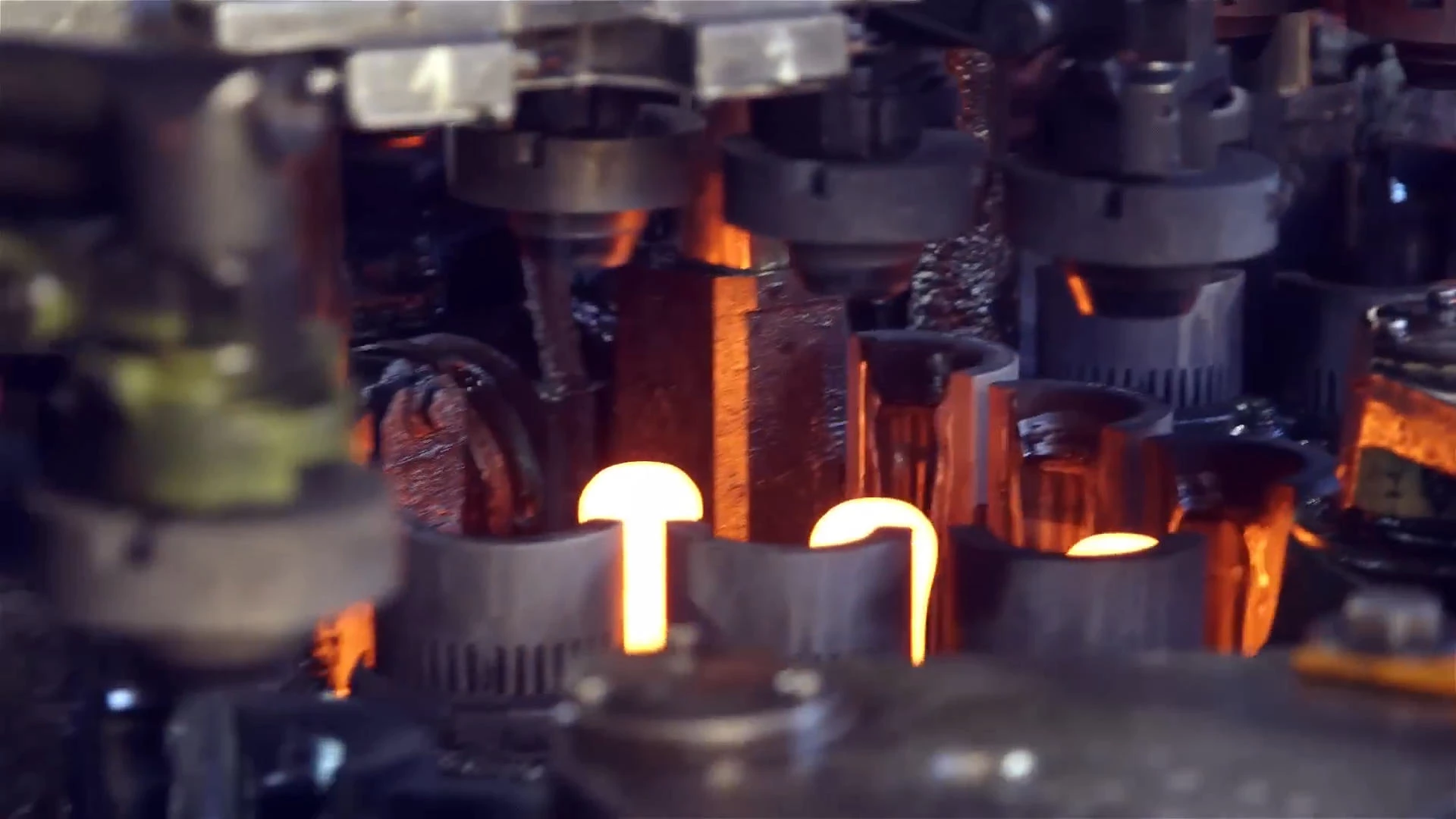

4. Glass Bottle Forming Process

Bottle forming is the most mechanical—and often the most misunderstood—part of manufacturing.

There are two mainstream methods:

- Blow-and-Blow (narrow neck bottles like beer, soda)

- Press-and-Blow (wide-mouth jars, premium spirits bottles)

The Initial Mold (Blank Mold)

Here, a controlled gob enters the blank mold and forms a parison—the preliminary shape that looks nothing like a finished bottle. In PB forming, a plunger pushes the glass into shape first, improving wall uniformity.

The Final Mold

The parison transfers to a final mold, where it is blown with air into its final form.

Case: Shoulder Thickening in a Saxco Project

Saxco once requested a premium 750 ml spirits bottle with a heavy base and a fairly complex shoulder design. During the trial run, we noticed the shoulder region becoming too thick, enough that light refraction looked inconsistent.

The problem?

The plunger temperature was slightly high. Hot plungers tend to hold onto glass longer, pulling material toward the shoulder.

We:

- reduced plunger temperature

- adjusted cooling air

- widened the take-out timing by 0.03 seconds

The next run produced much cleaner shoulders.

Most customers never see these subtle adjustments, but each one directly affects visual quality.

5. Annealing Process in Glass Manufacturing

Newly formed bottles come out hot and full of internal stress. If you cooled them instantly, many would crack right away.

That’s why they go through a long annealing lehr—essentially a controlled heating and cooling tunnel.

The temperature gradually ramps down from around 550–600°C to room temperature in a carefully controlled curve.

If the curve is off, you get:

- stress cracks

- shipping breakage

- bottom checks

- weak pressure resistance

- neck cracking during capping

Case: A Spanish Client’s High Breakage Rate

A Spanish olive oil producer once told us that their breakage rate went up sharply during shipment. My first suspicion was improper annealing. We checked the lehr curve and found that zone 4 cooled too quickly due to a malfunctioning fan damper.

The difference was small—less than 20°C—but enough to trap stress. We rebalanced the annealing curve, and breakage dropped dramatically in the next batch.

Annealing is invisible to buyers, yet it decides whether a bottle is strong or fragile.

6. Hot-End and Cold-End Coating

Two coatings protect bottles during conveying and filling:

- Hot-end coating: applied at high temperature (tin oxide or titanium oxide)

- Cold-end coating: typically polyethylene spray applied before packing

Without sufficient coating, bottles scratch each other on the line, creating micro-cracks invisible to the naked eye.

Case: Labeling Issues for InnovativeSourcing

InnovativeSourcing once mentioned that their labeling machine was occasionally stopping due to slippage or unexpected friction on the bottle surface. Mechanical issues were unlikely, so we checked the surface slip coefficient and found the cold-end coating was lighter than usual.

Once we increased the coating density, the bottles moved smoothly on their labeling line again.

These coatings may seem unimportant, but they affect both filling efficiency and long-term bottle integrity.

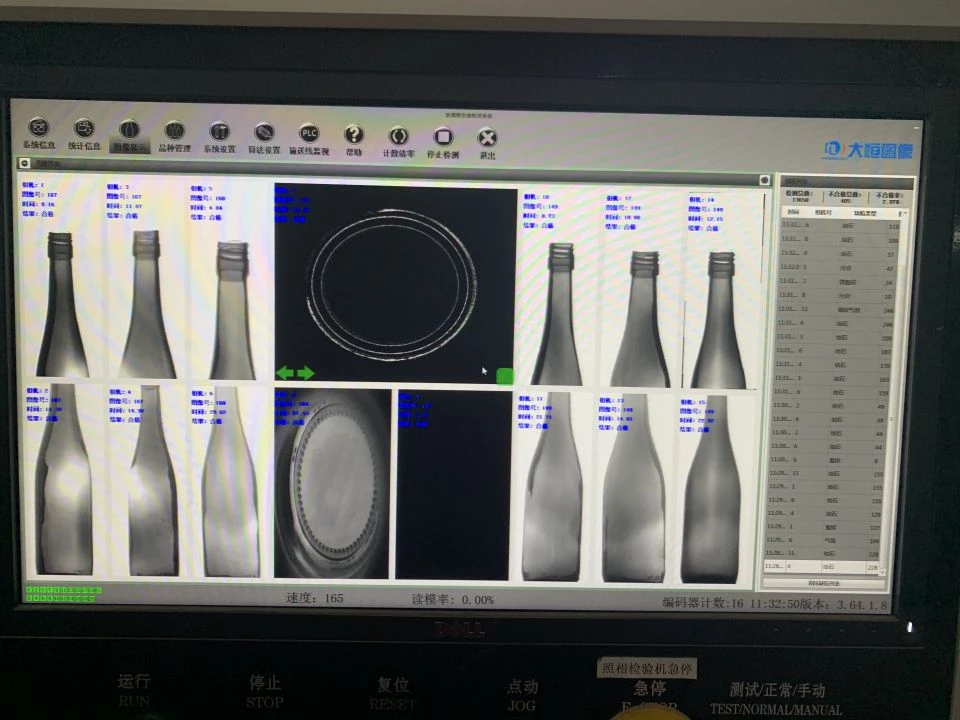

7. Automatic and Manual Bottle Inspection

Modern production uses automated inspection systems to check:

- wall thickness

- height, diameter

- vertical load

- finish dimensions

- internal pressure

- stress patterns

- foreign particles or stones

However, machines don’t detect everything.

Experienced inspectors (typically with 7+ years on the line) can visually identify:

- uneven shoulder transitions

- faint forming lines

- slight color variations

- weak embossing

- incorrect surface gloss

- parison sag marks

- mold mismatch effects

In one review session for West Coast Bottles, an inspector spotted subtle asymmetry in the embossing that cameras didn’t flag. It turned out the blank-side mold hanger bolt had loosened slightly. It saved us from producing several pallets of bottles with cosmetic defects.

Good inspection is half machine, half trained human intuition.

8. Packing and Palletizing for Export

Even the strongest bottles can break during shipping if the packing isn’t right.

Export-oriented factories typically use:

- cardboard separators

- shrink-wrapped pallets

- corner boards

- anti-slip sheets

- fumigated pallets

Different customers require different stability.

Case: Long-Distance Shipping for Country Malt Group

Country Malt Group’s shipments often travel several legs: sea → rail → truck. That combination subjects pallets to vibration, lateral forces, and long periods of stacked weight.

For them, we added:

- an extra separator layer

- reinforced top-frame board

- thicker shrink film

Breakage dropped noticeably after adjustment.

Packing is the last step but arguably one of the most costly to get wrong.

9. Why Buyers Should Understand the Manufacturing Process

A bottle is not just a container.

It’s a sequence of:

- chemical purity

- temperature control

- mechanical forming

- mold management

- thermal stress engineering

- coating science

- line inspection

- logistics protection

When customers like West Coast Bottles, Saxco, InnovativeSourcing, or Country Malt Group engage deeply with the production process, we achieve better results with fewer surprises.

Buyers who understand the manufacturing basics can:

- specify tolerances more realistically

- select better mold designs

- communicate filling-line needs clearly

- judge quality issues more accurately

- reduce unnecessary costs

- avoid misunderstandings

As an engineer, I appreciate when a customer asks informed questions. It makes our work smoother and the final product far more reliable.

After more than a decade in this industry, my respect for glass manufacturing has only grown. Every bottle may look identical, but behind each one is a precise sequence of decisions, adjustments, and engineering compromises.

And while automation has advanced, glass production still relies heavily on human experience.

A furnace operator learns to “read” the melt.

A mold technician feels when something sounds slightly off.

An inspector can spot a faint distortion that no machine catches.

This combination of heat, chemistry, machinery, and human judgment is what makes glass bottle manufacturing both challenging and rewarding.

If you’re planning to source bottles—whether you’re in food, beverages, cosmetics, or something else—I hope this technical perspective helps you evaluate suppliers with more confidence and less guesswork.

Questions & Answers

In the press-and-blow method, a plunger first presses the gob into shape, then the parison is blown — this gives better wall distribution and is commonly used for wide-mouth jars or premium spirits bottles.

1. Clear raw-material composition and cullet ratio

2. Temperature logs for furnace and forehearth zones

3. Forming method specification (press/blow) and machine section counts

4. Inspection protocols (AQL sampling, vertical load, wall thickness)

5. Export packaging design (pallet stability, anti-slip layers, shrink wrap)

Understanding the full process helps buyers spot weak links early, avoid surprises in overseas shipments.

Author: Long Chen

Long Chen has been working in the glass packaging industry for more than 20 years.

He specializes in furnace operation, forming process optimization, mold design, and production troubleshooting for export-grade glass containers.

He has participated in technical projects serving clients in the U.S., Europe, Southeast Asia, and the Middle East, including cooperation on bottle development and manufacturing adjustments for companies such as InnovativeSourcing and Country Malt Group.