Advantages and highlights

- High transmittance barrier technology: high white glass material is used to effectively filter 97% of ultraviolet rays and maintain the stability of the flavor of the beer

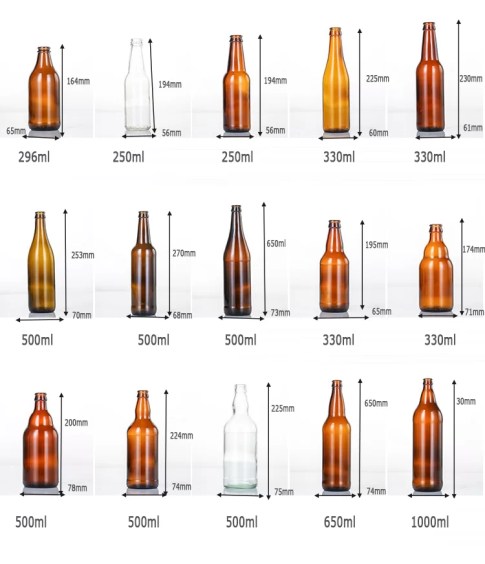

- Industrial-grade structural design: 280mm standard height with 73.86mm grip diameter, suitable for mainstream filling equipment such as Ball and O-I

- Circular economy certification: in line with the EU EN 12758 standard, supporting unlimited recycling and reuse of green packaging solutions

Typical application scenarios

This specification container is widely used in the field of craft beer packaging, especially for the storage of light-sensitive beer such as IPA and Stout. Some customers extend it to high-end beverage packaging such as organic juice and handmade cold brew coffee, and form supporting supply chain cooperation with Kombucha brands such as GT’s Synergy.

Supporting component solutions

The standard configuration includes a 26mm crown cap bite slot, and an optional SKS-Bosch automatic capping system dedicated bottle mouth. Provide shockproof EPE partition inner tray to support pallet stacking solutions that seamlessly connect with KHS filling lines.

| Parameters | Technical indicators |

|---|---|

| Net weight of a single bottle | 358±5g |

| Compressive strength | ≥1.2MPa |

| Light transmittance | <3% (400-500nm band) |

| Thermal shock temperature difference | 60℃ |

Customized service capabilities

Support brand owners to carry out the following in-depth customization:

- Screen printing on bottle body (Pantone color matching ≥95%)

- Embossed LOGO pressing (depth 0.3-0.8mm adjustable)

- Anti-counterfeiting inkjet area reserved

Cooperation cases include providing exclusive batch coding solutions for American craft beer brand Stone Brewing.

Surface treatment and deep processing

Adopting German Heinz Glass process standards, optional:

- Food-grade water-based spraying (FDA 21 CFR certification)

- Electrostatic dust prevention treatment

- Aseptic cleaning pre-packaging

Note: High borosilicate material processing services are not provided for the time being

Supply chain guarantee system

The dual production base layout ensures that the annual production capacity exceeds 20 million pieces, equipped with a warehouse management system that has passed the SGS factory inspection. Establish strategic cooperation with Maersk and COSCO Shipping, and support various trade terms such as FOB/CIF.

Procurement Policy Description

- Standard minimum order quantity: 20GP container (about 18,000 pieces)

- Ladder price: VIP agreement price for annual purchase volume of 1 million pieces

- Payment method: LC 60-day account period is accepted

Global market distribution

Main service areas include:

- North American craft beer gathering belt (Portland, Denver, etc.)

- Traditional European beer producing areas (Munich, Brussels)

- Emerging markets in Oceania (Melbourne, Auckland)

Quality commitment terms

Implement full-process QMS monitoring and provide:

- Batch traceability report

- Damage rate compensation mechanism (transport loss ≤ 0.8%)

- 12-month quality assurance period

The current inventory can support emergency orders to be shipped out within 72 hours. Please contact us to obtain the latest customs compliance documents and FDA registration codes. For first-time customers, free sample adaptation testing is provided (limited to 3 surface treatment process options).

Note: The third-party brands mentioned in this article are only for industry application descriptions and do not constitute commercial association endorsements. Technical parameters may be fine-tuned as process improvements are made, and the specific details shall be subject to the real-time test report.