Avantages du produit

- Le matériau en verre sodocalcique a été traité avec un renforcement secondaire, avec une résistance à la compression de 8 à 12 bars, ce qui répond aux normes de sécurité de contact alimentaire de la FDA.

- Technologie anti-empreintes digitales à surface mate, adaptée aux exigences de tonalité visuelle des marques haut de gamme telles que Dom Pérignon et Krug

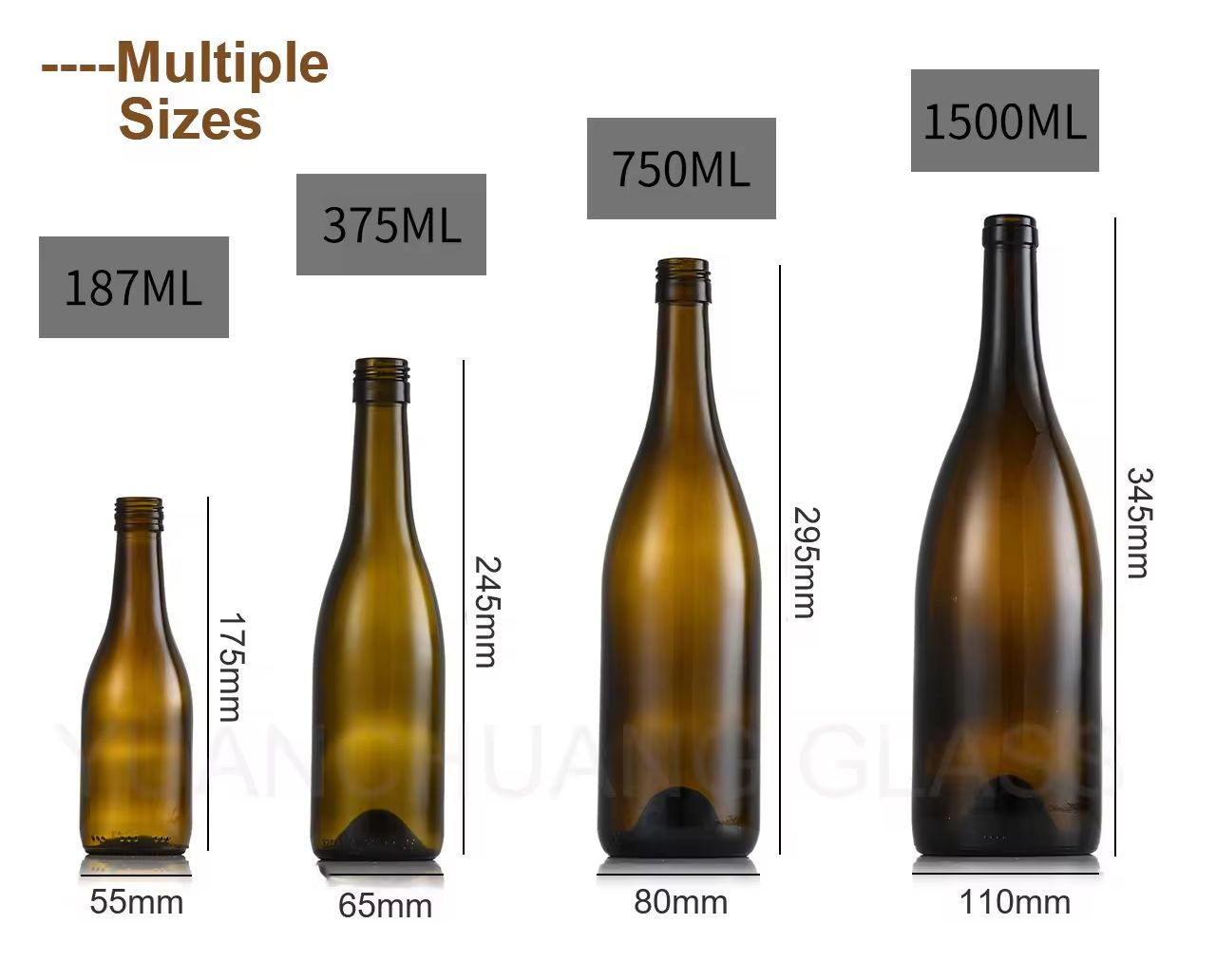

- Capacités de personnalisation flexibles de tous les paramètres, conception de la bouteille couvrante, spécifications de capacité (187 ml-3 L), système d'étanchéité (bouchon à vis en liège/métal)

Scénarios d'application et adaptabilité de l'industrie

Conçu pour le champagne, les vins mousseux et les spiritueux en édition limitée, il est particulièrement adapté aux vins devant être conservés à l'abri de la lumière. Le substrat en verre foncé bloque les rayons ultraviolets 99% afin d'éviter la détérioration du vin causée par les réactions photochimiques. Cette caractéristique est largement utilisée dans les collections de vins millésimés de marques telles que Bollinger et Veuve Clicquot.

Composants de support et spécifications techniques

| Catégories de composants | Solutions optionnelles |

|---|---|

| Système d'étanchéité | Bouchon en liège naturel (diamètre 29/31 mm), bouchon en aluminium plaqué or (compatible avec les équipements de scellage Codorníu) |

| Accessoires de protection | Revêtement tampon EPE personnalisé (compatible avec les standards des coffrets cadeaux Moët & Chandon) |

| Solutions logistiques | Un emballage de renforcement de palette antichoc selon les conditions FCA/FOB peut être fourni |

Capacités de conception et de production personnalisées

- Développement de la forme de la bouteille: Prend en charge la reproduction de bouteilles de champagne classiques (comme la forme de la bouteille Salmanazar) et le développement de bouteilles de forme spéciale (se référer à la série d'art Piper-Heidsieck)

- Adaptation des capacités: Couvre tous les systèmes de spécifications tels que les 750 ml standard, Magnum (1,5 L), Jéroboam (3 L)

- Traitement de surface: Galvanoplastie en gradient (certification de la carte de couleurs Pantone), sérigraphie à glaçure haute température (résistant au lavage à l'eau à 80 °C), profondeur de relief de 0,3 à 1,2 mm

Indicateurs techniques de traitement en profondeur

La sérigraphie est réalisée avec un vernis importé d'Europe, et l'adhérence des couleurs est conforme au test de grille ISO 2409. Le fond de la bouteille est concave sur une profondeur de 3,5 cm pour garantir la résistance à la pression de la fermentation secondaire. La tolérance au goulot est contrôlée à ± 0,15 mm, compatible avec les équipements de remplissage standard du groupe LVMH.

Système de service et garantie de livraison

Nous assurons un accompagnement complet, de la modélisation 3D à la production en série, et finalisons la confirmation du premier échantillon sous 15 jours ouvrés. Nous prenons en charge le transport par conteneurs LCL afin de réduire les coûts d'approvisionnement des petites et moyennes séries. Pour les commandes urgentes, nous pouvons activer le canal rapide pour un délai de livraison de 30 jours.

Politique de coopération et conditions commerciales

- Quantité minimum de commande: 5 000 pièces pour les modèles standards (prend en charge le chargement mixte de plusieurs références), 50 000 pièces pour les modèles personnalisés en profondeur

- Conditions de garantie: Réémission gratuite si le taux de dommage dépasse 0,3% à l'arrivée au port, et un service de traçabilité de qualité de 12 mois est fourni

- Mode de paiement: Accepter TT/LC, paiement anticipé 30% + paiement 70% après avoir vu la copie du connaissement

Certification du marché principal et de l'industrie

Le produit a obtenu la certification CE et est principalement utilisé par les groupes de restauration européens (comme Accor Hotel Supply Chain), les caves à vin nord-américaines et les circuits de vente hors taxes du Moyen-Orient. Ces dernières années, il a obtenu la certification de fournisseurs de second rang de fabricants tels que GHMumm et Taittinger.

Avis de non-responsabilitéLes marques internationales mentionnées dans cet article sont utilisées uniquement à titre d'illustration pour illustrer des scénarios d'application sectoriels et n'ont aucun lien commercial direct avec elles. Les droits de propriété intellectuelle de toutes les solutions personnalisées appartiennent à l'acheteur afin de garantir le respect des réglementations internationales en matière de marques.