Ventajas del producto

La botella de vidrio ámbar con tapa oscilante de 500 ml está diseñada para las necesidades de almacenamiento de bebidas, teniendo en cuenta tanto la practicidad como los efectos de comunicación visual con los estándares industriales:

- Estructura de sellado de larga duración:La hebilla de metal y la junta de goma de calidad alimentaria forman una barrera física que puede mantener la hermeticidad durante más de 6 meses para garantizar el efecto de fermentación secundaria de las bebidas carbonatadas.

- Sistema de protección de material fotosensible:El material de vidrio ámbar filtra los rayos ultravioleta 99%, retrasando eficazmente la descomposición del lúpulo y la atenuación de la actividad de la levadura.

- Diseño de adaptación a múltiples escenarios:El cuerpo de la botella tiene un espesor de 3,2 mm y ha pasado la prueba de impacto de 0,4 julios, lo que es adecuado para el funcionamiento a alta velocidad de líneas de llenado y entornos de transporte de cadena de frío.

Áreas de aplicación funcional

Este producto satisface las necesidades de envasado de las principales empresas de bebidas de todo el mundo:

- Bebidas fermentadas: cerveza artesanal, kombucha, sidra y otros productos que requieren fermentación secundaria

- Almacenamiento funcional de líquidosCafé frío, aceite de hierbas, jarabe artesanal.

- Escenarios de exhibición comercial: botellas de cóctel personalizadas para bares, botellas de salsa exclusivas para cadenas de restaurantes

Soluciones de personalización personalizadas

Ofrecemos una solución de embalaje de marca con proceso completo:

| Tipo de personalización | Parámetros del proceso | Escenarios aplicables |

|---|---|---|

| Serigrafía | Precisión de sobreimpresión de cuatro colores ±0,15 mm | Logotipo de marca logotipo permanente |

| Proceso de estampación en caliente | Espesor de la lámina de oro: 0,12-0,15 μm | Embalaje de producto de edición limitada |

| Tratamiento esmerilado | Atomización uniforme de arena de diamante de malla 270 | Optimización del área de agarre antideslizante |

| Grabado en relieve | Precisión CNC 0,01 mm | Número exclusivo para edición conmemorativa |

Capacidad de procesamiento profundo de grado industrial

El sistema de producción ha pasado la certificación de seguridad alimentaria ISO 22000, con una configuración especial:

- Tratamiento de fortalecimiento de la boca del biberónLa tecnología de pulido con llama elimina las microgrietas y el valor de presión de ruptura alcanza los 1,8 Mpa.

- Sistema de alivio del estrés: El horno de recocido escalonado hace que el valor de tensión del vidrio sea ≤4 niveles

- Línea de envasado limpio: El taller de purificación de 100.000 niveles completa el etiquetado automático y el envasado al vacío

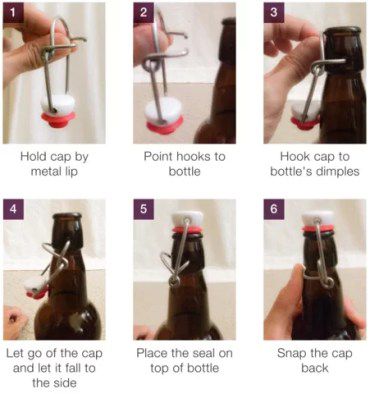

Cómo montar las botellas con tapa abatible

El montaje del mecanismo de basculación es sencillo y eficaz. Siga estos pasos:

- Sujete el tapón por el labio metálico.

- Dirija los ganchos hacia la botella.

- Engancha el tapón en los hoyuelos de la botella.

- Suelte el tapón y déjelo caer hacia un lado.

- Coloque la junta de goma en la parte superior de la abertura de la botella.

- Vuelva a colocar el tapón en su sitio, asegurándose de que quede bien sellado.

Una vez montadas, las botellas de tapa abatible están listas para su uso inmediato. Este diseño es fácil de usar, lo que hace que el proceso de embotellado sea más rápido y eficiente tanto para los cerveceros caseros como para los fabricantes.

Servicio de cadena de suministro global

20 años de experiencia como fabricante profesional de envases de vidrio y cobertura de red de servicios:

- Mercado europeo: Establecer una adaptación técnica con fabricantes de equipos de llenado como KHS y Krones

- Canal norteamericano: Aprobó la certificación de la FDA y admite la entrega directa desde los almacenes de Amazon FBA

- Centro de Asia y el Pacífico: El puerto de Qingdao/Ningbo tiene 3 barcos exprés por semana, que llegan al puerto de Los Ángeles el día 15.

Política de adquisiciones paso a paso

Implementar un mecanismo transparente de precios al por mayor:

- Orden básica: Carga mixta de gabinete completo (40HQ puede acomodar 31,920 piezas)

- Cooperación estratégica: Los clientes con contrato marco anual disfrutan de una gestión de almacenamiento exclusiva

- Orden de emergencia: Producción en 72 horas para pedidos urgentes inferiores a 15.000 piezas

Distribución del mercado objetivo

Atendemos principalmente las siguientes áreas de alto crecimiento:

- Taller de cerveza artesanal (evaluación comparativa de los modelos operativos de Stone Brewing y BrewDog)

- Marcas de cadenas de alimentos orgánicos (consulte las necesidades de expansión de la línea de productos de Whole Foods)

- Grupos hoteleros y de restauración (para atender las compras personalizadas de empresas como Marriott)

Sistema de verificación de calidad

Cada lote de productos pasa:

- Prueba de presión interna: 1,6 MPa durante 3 minutos sin fugas

- Detección de carga vertical: ≥150 kg de presión axial

- Prueba de choque de frío y calor: ciclo de diferencia de temperatura de 0 a 80 ℃ 20 veces

(Nota: Los parámetros técnicos específicos y los documentos de certificación se pueden obtener en el libro blanco del producto)

Canal de consulta técnica

El equipo de ingeniería proporciona:

- Solución de adaptación de la línea de llenado (aplicable a la serie Innofill de Krones)

- Sugerencias de optimización del embalaje (reducir la tasa de daños durante el transporte a menos de 0,31 TP3T)

- Consulta regulatoria (cumplimiento de las normas de materiales en contacto con alimentos UE 1935/2004)

Observaciones: Las especificaciones del producto pueden ajustarse debido a actualizaciones tecnológicas. Para obtener la tabla de parámetros más actualizada, contacte con el asesor técnico. La materia prima de producción es vidrio de alta blancura y no se utilizan materiales con alto contenido de borosilicato. Para obtener información detallada sobre los indicadores físicos y químicos, consulte el informe del Certificado de Análisis (COA).