Vorteile Fokus

Unsere bernsteinfarbene 500-ml-Flasche mit Klappverschluss ist auf die Kernbedürfnisse der Getränkeverpackungsindustrie ausgerichtet und bietet die folgenden differenzierten Werte:

- Druckfeste Konstruktion: Der Flaschenkörper ist 3,2 mm dick, besteht den 0,4-Joule-Aufpralltest, entspricht dem US-Standard ASTM C149 und ist für die Anforderungen der Nachgärung kohlensäurehaltiger Getränke geeignet.

- Lichtempfindliches Schutzsystem: Braunglas blockiert 99% ultraviolette Strahlen, verzögert den Hopfenabbau und die Abschwächung der Hefeaktivität und verlängert die Haltbarkeit auf 6 Monate.

- Industrielles Anpassungsdesign: Der Flaschenmündungsdurchmesser beträgt 79 mm ± 1,5 mm und entspricht damit genau den gängigen Abfüllanlagen wie Krones Innofill.

Abdeckung mehrerer Anwendungsszenarien

Dieses Produkt erfüllt die vielfältigen Verpackungsanforderungen globaler Getränkeunternehmen:

- Fermentierte Getränke: Craft Beer, Kombucha, Apfelwein und andere Kategorien, die eine kontinuierliche Gärung erfordern

- Funktionale Flüssigkeitsspeicherung: kalt gebrühter Kaffee, Kräuteröl, handgemachter Sirup

- Kommerzielle Anzeigeszenarien: Individuell gestaltete Cocktailflaschen für Bars, exklusive Soßenflaschen für Restaurantketten

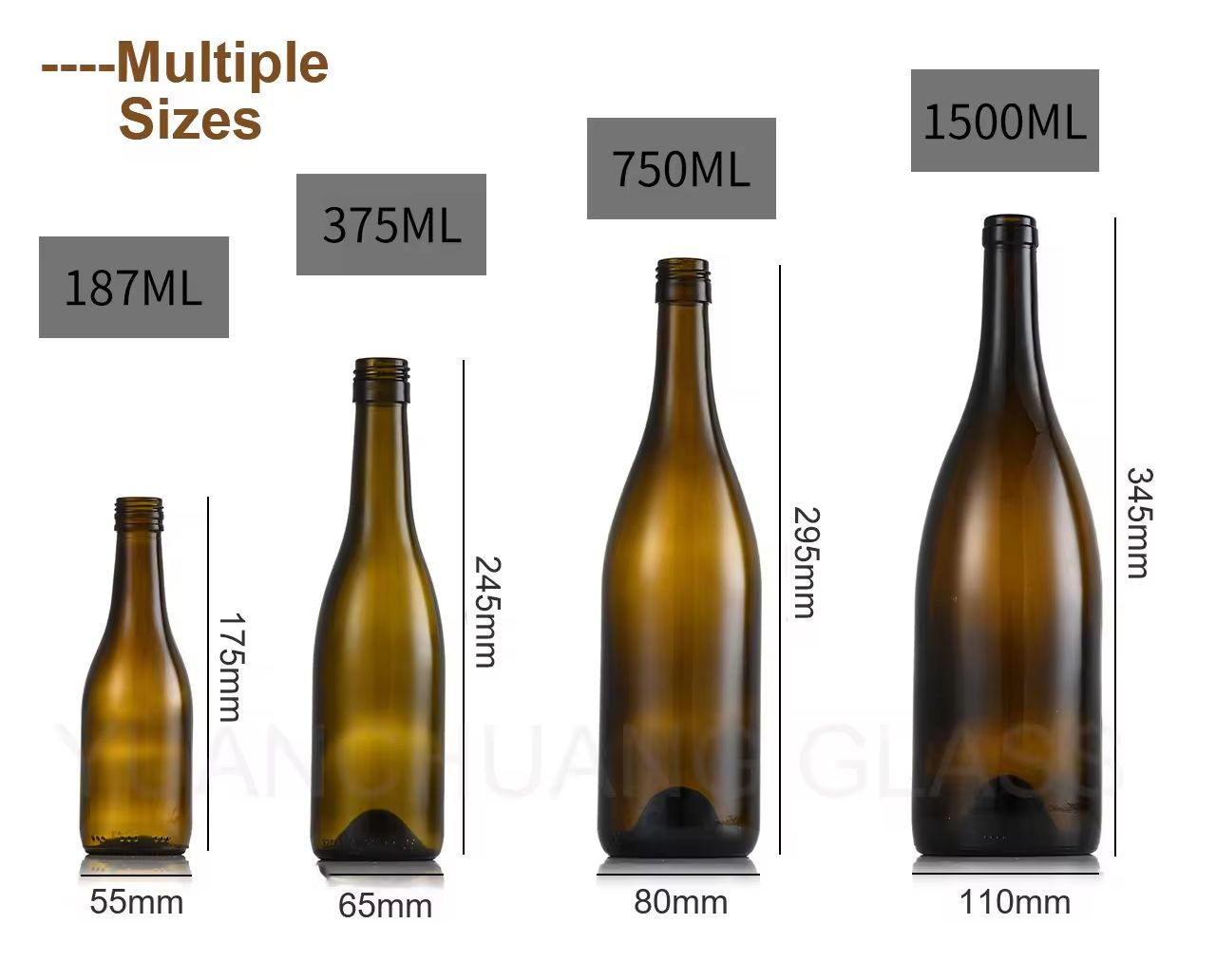

Volldimensionaler Anpassungsservice

Bieten Sie eine komplette Markenlösung von der Flasche bis zur Verpackung:

| Prozesstyp | Technische Parameter | Typische Anwendungsszenarien |

|---|---|---|

| Siebdruck | Vierfarben-Überdruckgenauigkeit ±0,15 mm | Markenlogo, permanentes Logo |

| Heißprägeverfahren | Goldfoliendicke 0,12–0,15 μm | Produktverpackung in limitierter Auflage |

| Mattierte Behandlung | 270 Mesh Diamantsand gleichmäßige Zerstäubung | Rutschfeste Griffflächenoptimierung |

| Reliefgravur | CNC-Gravurgenauigkeit 0,01 mm | Exklusive Gedenkausgabe mit Nummer |

Industrielle Produktionsstandards

Das Produktionssystem hat die ISO 22000-Zertifizierung bestanden und zu den wichtigsten Prozessen gehören:

- Flaschenmund-Stärkungsbehandlung : Durch Flammpolieren werden Mikrorisse beseitigt und der Berstdruck erreicht 1,8 MPa

- Stressabbausystem : Durch den schrittweisen Glühprozess wird der Glasspannungswert ≤4 Stufen

- Saubere Verpackungslinie : Reinigungswerkstatt auf 100.000 Ebenen vervollständigt automatische Etikettierung und Vakuumverpackung

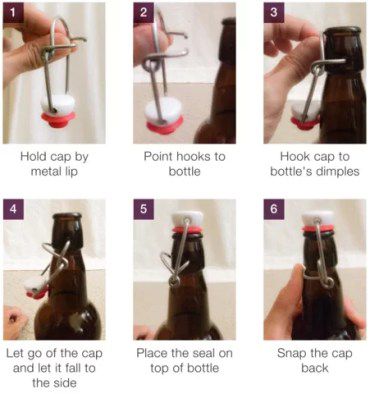

Zusammenbau von EZ Cap-Flaschen

Befolgen Sie diese Schritte für eine einfache Montage:

- Halten Sie die Kappe an der Metalllippe fest.

- Richten Sie die Haken auf die Flasche.

- Haken Sie den Verschluss an den Vertiefungen der Flasche ein.

- Lassen Sie die Kappe auf die Seite fallen.

- Setzen Sie die Gummidichtung oben auf die Flaschenöffnung.

- Setzen Sie die Kappe wieder ein, um die Dichtung zu sichern.

Globales Lieferkettennetzwerk

20 Jahre Erfahrung in der Herstellung von Glasbehältern, Abdeckung des Servicenetzwerks:

- Europäischer Markt : Abschluss einer technischen Anpassungsvereinbarung mit den Herstellern von KHS-Abfüllanlagen

- Nordamerikanischer Kanal : FDA-Zertifizierung bestanden und unterstützt Direktlieferung aus Amazon FBA-Lagern

- Asien-Pazifik-Drehscheibe : Der Hafen Qingdao/Ningbo hat 3 Expressschiffe pro Woche, die den Hafen von Los Angeles am 15. erreichen

Leiter-Einkaufspolitik

Transparenter Mengenpreismechanismus erfüllt die Anforderungen unterschiedlicher Größenordnungen:

- Grundordnung: Voller Schrank mit gemischter Beladung (40HQ bietet Platz für 40.000 Teile)

- Strategische Zusammenarbeit: Kunden mit Jahresrahmenvertrag genießen exklusives Lagermanagement

- Notverordnung: 72-Stunden-Produktionsplanung für dringende Bestellungen unter 15.000 Stück

Hauptzielmarkt

Konzentrieren Sie sich auf die Bedienung der folgenden wachstumsstarken Bereiche:

- Craft-Beer-Workshop (Benchmarking der Betriebsmodelle von Stone Brewing und BrewDog)

- Marken der Bio-Lebensmittelkette (siehe Bedarf von Whole Foods zur Erweiterung der Produktlinie)

- Hotel- und Gastronomiegruppen (lernen Sie die maßgeschneiderte Beschaffung von Marriott und anderen Unternehmen kennen)

Qualitätsüberprüfungssystem

Jede Produktcharge durchläuft dreifache Tests:

- Innendrucktest: 1,6 MPa für 3 Minuten ohne Leckage

- Vertikaler Belastungstest: ≥150kg axialer Druck

- Hitze- und Kälteschocktest: 20-maliger Temperaturunterschiedszyklus von 0–80 °C

(Hinweis: Die vollständigen technischen Parameter können Sie dem Whitepaper zum Produkt entnehmen.)

Technische Mehrwertdienste

Das Engineering-Team bietet:

- Lösung zur Anpassung der Abfülllinie (kompatibel mit der Krones Innofill-Serie)

- Vorschläge zur Verpackungsoptimierung (Transportschadensrate ≤ 0,3%)

- Regulatorische Beratung (konform mit der EU-Norm 1935/2004 für Materialien, die mit Lebensmitteln in Berührung kommen)

Anmerkungen: Das Produkt besteht aus hochweißem Glas. Physikalische und chemische Indikatoren finden Sie im COA-Bericht. Für kundenspezifische Dienstleistungen ist eine Bestätigung des Entwurfsplans 45 Tage im Voraus erforderlich. Der Eilzuschlag beträgt 151 TP3T auf das reguläre Angebot.