في صناعة المشروبات الروحية، الزجاجة ليست مجرد وعاء؛ بل هي امتداد لقيمة العلامة التجارية. تُحسّن الزجاجات عالية الجودة صورة المنتج، وتحمي جودة المشروبات الروحية، وتؤثر بشكل مباشر على قرارات الشراء لدى المستهلكين. إليكم 12 من أكثر العلامات التجارية تأثيرًا في العالم. مصنع زجاجات الويسكيs، التي جعلها تصميمها المبتكر وإنتاجها المستدام وإمداداتها المرنة الشركاء المفضلين لأفضل مصانع التقطير:

قائمة بأكبر 12 شركة مصنعة لزجاجات الويسكي في العالم

1. شركة OI Glass, Inc. (الولايات المتحدة الأمريكية)

أكبر مُصنّع للزجاجات الزجاجية في العالم، مع ما يقارب 70 مصنعًا في أكثر من 20 دولة. نقاط القوة الأساسية:

- يستخدم عملية صديقة للبيئة باستخدام الزجاج المعاد تدويره 60% (Cullet)، بهدف تحقيق التبني الكامل بحلول عام 2030.

- توفير تصميمات زجاجات مخصصة للعلامات التجارية مثل Johnnie Walker و Dewar's.

- يتجاوز الإنتاج السنوي 10 مليارات زجاجة، مما يدعم الطلبات الكبيرة الحجم والتسليم السريع.

2. شركة صنفكت للتغليف (الصين)

متخصصة في تخصيص زجاجات المشروبات الروحية الراقية، وتخدم كل من مصانع البيرة الحرفية الصغيرة والعلامات التجارية الكبيرة.

- يقدم النقش والحفر والطلاء المصنفر.

- كميات الطلب الدنيا المرنة (MOQs) ومسودات التصميم ثلاثية الأبعاد في غضون 48 ساعة.

- يتوافق مع معايير FDA/EC ويتمتع بشهادة شراكة طويلة الأمد مع علامات تجارية مثل Chivas.

3. بي جي بي (الصين)

تشتهر بقدرتها العالية على نفاذ الضوء ومقاومتها للصدمات.

- تتضمن الخدمات المتكاملة تصميم OEM/ODM وتطوير القوالب والمعالجة الزخرفية.

- طباعة الشاشة. دقة الطباعة تصل إلى 0.1 مم.

- من الرسم إلى العينة الأولى في 15 يومًا، ويمكن تسليم الطلبات التي تتجاوز المليون حجمًا في 30 يومًا.

4. سافيرجلاس (فرنسا)

علامة تجارية رائدة في مجال زجاجات النبيذ الفاخرة، وتبلغ حصتها 35% في سوق المنتجات الفاخرة العالمية:

- تصميم قاعدة "النيزك البلوري" الحاصل على براءة اختراع يعزز العمق البصري

- التشطيبات الفنية مثل تطعيم رقائق الذهب عيار 24 قيراطًا والتشطيبات المرسومة يدويًا

- تغليف مخصص للزجاجات القابلة للتجميع مثل Yamazaki 30 Year Old

5. شركة ألايد جلاس (المملكة المتحدة)

معيار جديد في زجاجات الويسكي الفاخرة، بالتعاون مع ماكالان ورويال سالوت:

- زجاجات طبعة محدودة منفوخة يدويًا إلى جانب الإنتاج الضخم الآلي

- توفير حلول للظلال الزجاجية الخاصة مثل الأزرق الكوبالتي والأخضر العنبري

- نظام تتبع البصمة الكربونية المعتمد وفقًا لمعيار ISO 14067

6. التعبئة والتغليف في المختبر (المكسيك)

شركة رائدة في السوق الأمريكية الشمالية، مع قرن من الخبرة في تكنولوجيا الزجاج:

- يقلل تصميم الزجاجة الفريد "خفيف الوزن ذو القاعدة السميكة" من استخدام الزجاج بنسبة 30% مع تحسين الاستقرار.

- تعمل أنظمة إعادة التدوير ذات الحلقة المغلقة على معالجة 99% من نفايات الإنتاج.

- المورد الأساسي لشركة جاك دانيلز.

7. مجموعة ستولزلي للزجاج (النمسا)

شركة زجاج أوروبية عمرها قرن من الزمان تتمتع بمزايا تكنولوجية:

- عملية "التطوير في مكان واحد": التصميم التعاوني للزجاجة والفلين والملصق.

- تطوير أكثر من 300 تصميم جديد للزجاجة سنويًا، مع تسليم النماذج الأولية خلال 5 أيام.

- المورد الأساسي لشركة دييجيو.

8. زجاج MC (الصين)

خبراء في تحقيق التوازن بين فعالية التكلفة والتخصيص:

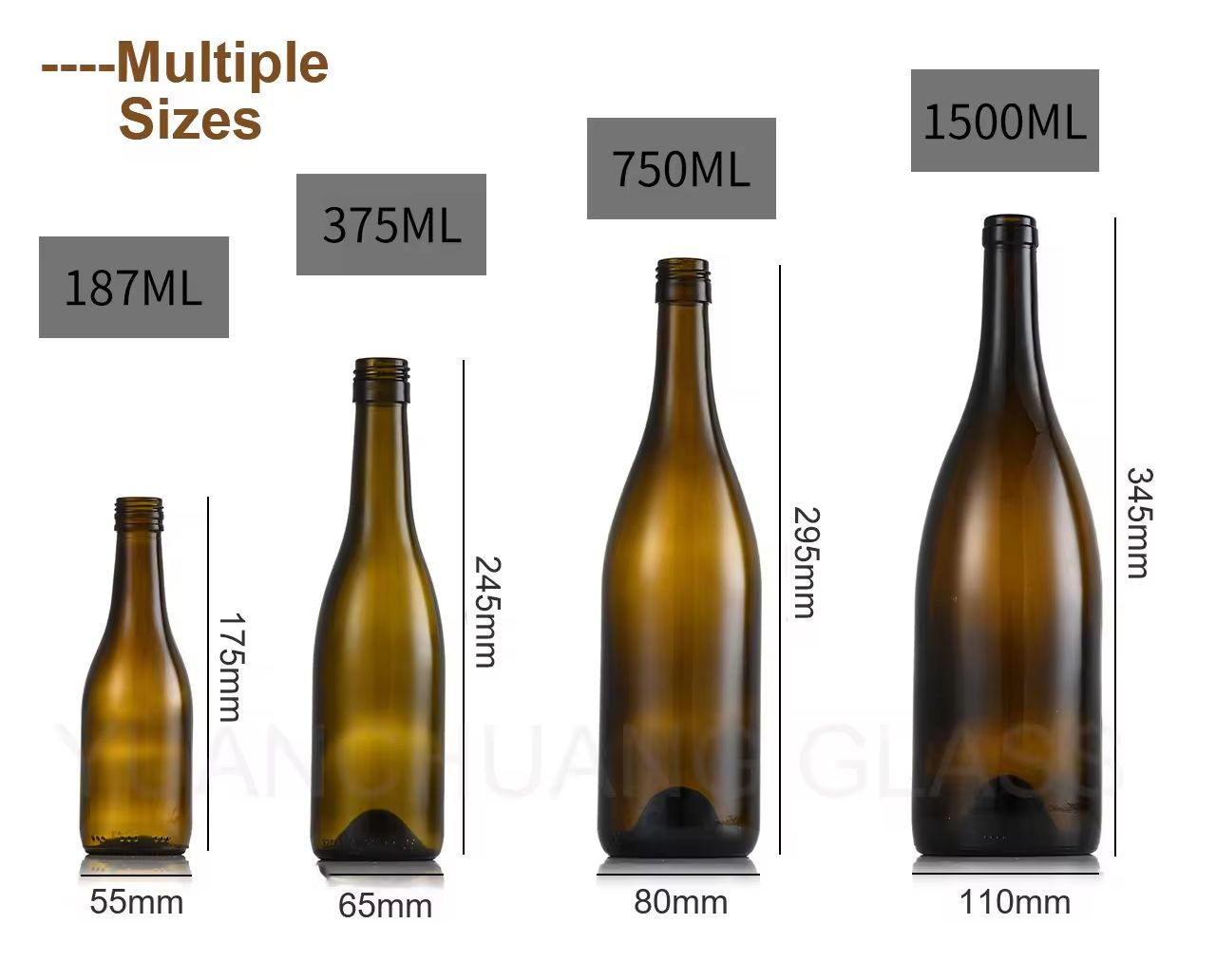

- تغطية مجموعة كاملة من الأحجام من 0.1 لتر إلى 1.75 لتر، مما يدعم تطوير الزجاجة ذات الشكل المخصص.

- تنتج تقنية الختم الساخن ملصقات معدنية.

- التسعير أقل من $0.80 لطلب أدنى يبلغ 100000 قطعة.

9. إمبريال باكيدجينج (الولايات المتحدة الأمريكية)

رائد في تكامل سلسلة التوريد:

- تسليم فوري لجميع الأحجام من 50 مل إلى 1.75 لتر في المخزون

- توصيل خلال 72 ساعة في جميع أنحاء الولايات الـ 48 السفلى في أمريكا الشمالية

- زجاجات جيم بيم ٥٠١TP٣T مُورَّدة من شركة إمبريال باكيدجينج ١٠. فيراليا (فرنسا).

ثاني أكبر مجموعة للتغليف الزجاجي في العالم:

- قدرة إنتاج سنوية تبلغ 1.7 مليار زجاجة، مما يدعم الطلبات بمئات الملايين

- علامة مكافحة التزوير الحاصلة على براءة اختراع على شكل حرف "V" على قاعدة الزجاجة

- الاستحواذ على شركة Allied Glass لتعزيز خطوط الإنتاج الراقية

11. بيتسون كلارك (المملكة المتحدة)

إرث من الابتكار التكنولوجي يمتد لـ 275 عامًا:

- متخصصون في الزجاج عالي الجودة للقوارير الصيدلانية المخصصة للويسكي الشعيري الفردي

- الزجاج الكهرماني المقاوم للأشعة فوق البنفسجية يطيل عمر الويسكي

- توفير حلول متكاملة لمكافحة التزييف في الفلين لشركة Glenlivet

12. إنسيرك (المملكة المتحدة)

رائدة في الإنتاج المستدام:

- أول خط إنتاج زجاجات زجاجية خالية من الكربون في العالم (يبدأ في عام 2024)

- تقلل تقنية فرن الوقود الحيوي من استهلاك الطاقة بمقدار 40%

- الشراكة مع باكاردي لتحقيق هدف 2030 المتمثل في التغليف الصديق للبيئة بالكامل

لماذا تختار الشركة المصنعة للزجاجات المهنية؟

كيف تؤثر الزجاجات على القيمة التجارية للويسكي؟

- تمييز العلامة التجارية: أشكال الزجاجات الفريدة تُبرز المنتجات على الرفوف. على سبيل المثال، تزيد زجاجات رويال سالوت المطلية بالسيراميك من ثباتها على الرفوف بنسبة 300%.

- ضمان الجودة: يقلل زجاج البورسليكات من التفاعلات الكيميائية الضوئية، مما يمنع تدهور الروح.

- التسعير المتميز: يمكن أن تؤدي تعبئة الزجاجات المخصصة إلى زيادة أسعار البيع بالتجزئة بنسبة 15-50% (على سبيل المثال، خط إنتاج The Macallan Lalique).

ما هي العمليات الأساسية لتصنيع الزجاجات؟

كيف توازن الزجاجات الحديثة بين الجمال والوظيفة؟

- تطور العفن:

- تقلل تقنية الطباعة الرملية ثلاثية الأبعاد وقت إنشاء النموذج الأولي إلى 72 ساعة

- تدعم القوالب المعيارية أكثر من 10 أشكال مختلفة من نفس شكل الزجاجة الأساسية

- عملية التعزيز:

- يزيد التبادل الأيوني من قوة ضغط الزجاج إلى ثلاثة أضعاف قوة الزجاج التقليدي

- تخلق تقنية الطلاء النانوي زجاجة "ذاتية التنظيف"، مما يقلل من بقايا بصمات الأصابع

- الابتكار البيئي:

- تقنية تخفيف الوزن: تم تقليل وزن الزجاجة سعة 750 مل من 560 جرامًا إلى 350 جرامًا (على سبيل المثال، زجاج OI)

- استخدام الزجاج المعاد تدويره 95% (عملية Encirc)

كيفية اختيار الشركة المصنعة؟

ما هي المؤشرات الرئيسية التي ينبغي تقييمها للطلبات بالجملة؟

- مطابقة القدرة: تفضل المصانع الصغيرة (<100000 قطعة) زجاج بي جي بي/زجاج ام سي; فيراليا/أوي للطلبات التي تتجاوز 10 ملايين.

- معايير الاعتماد: FDA (سلامة ملامسة الأغذية)، ISO 9001 (نظام الجودة)، BRCGS (معيار السلامة العالمي)

- خدمات إضافية:

- تخزين مجاني (تقدم Imperial 180 يومًا)

- تعويض معدل الكسر (تعهد الشركات المصنعة الرائدة بـ <0.3%)

- دعم عالمي للتخليص الجمركي المسبق (تغطي Stoelzle 27 دولة)

رؤى اتجاهات الصناعة: من المتوقع أن ينمو الطلب على زجاجات الويسكي بمقدار 12% بحلول عام 2025، مدفوعًا بالعلامات التجارية الحرفية الآسيوية (الصين واليابان وكوريا الجنوبية) وانتعاش سوق البوربون الأمريكي. أصبحت سلاسل التوريد المرنة ميزة تنافسية أساسية للمصنّعين، حيث حقق 80% من كبار المصنّعين دورة "تطوير منتجات جديدة لمدة 30 يومًا + تسليم عالمي لمدة 45 يومًا".

خاتمة

في قطاع تعبئة المشروبات الروحية، لا تزال الزجاجات الزجاجية وعاءً لا غنى عنه للويسكي الفاخر. من عملاق الصناعة البريطاني العريق بيتسون كلارك إلى شركة إنسيرك الرائدة في مجال الاستدامة، تُعيد الشركات المصنعة الرائدة صياغة معايير الصناعة من خلال التطوير التكنولوجي والخدمات المُخصصة. ينبغي على تجار الجملة المُحنّكين التركيز على ثلاثة مجالات رئيسية: مطابقة الموردين مع الطاقة الإنتاجية، وتحقيق امتيازات مميزة للعلامات التجارية من خلال عمليات مُتميزة، وخفض التكاليف على المدى الطويل من خلال سلسلة توريد صديقة للبيئة.

(تم تجميع المعلومات الواردة في هذه المقالة من تقرير قدرة تصنيع الزجاجات العالمية، والأوراق البيضاء الفنية من الشركات المصنعة الرائدة، وبيانات سلسلة توريد التقطير.)